Advanced Devices for Recycling Transformer Oil with Maximum Output

Advanced Devices for Recycling Transformer Oil with Maximum Output

Blog Article

Transform Waste Into Value With Advanced Transformer Oil Recycling

The makeover of waste right into value provides a critical possibility within the electric industry, especially with the lens of sophisticated transformer oil recycling. By utilizing advanced modern technologies, such as vacuum purification and purification systems, companies can recuperate important sources from utilized transformer oil while alleviating environmental risks.

Recognizing Transformer Oil

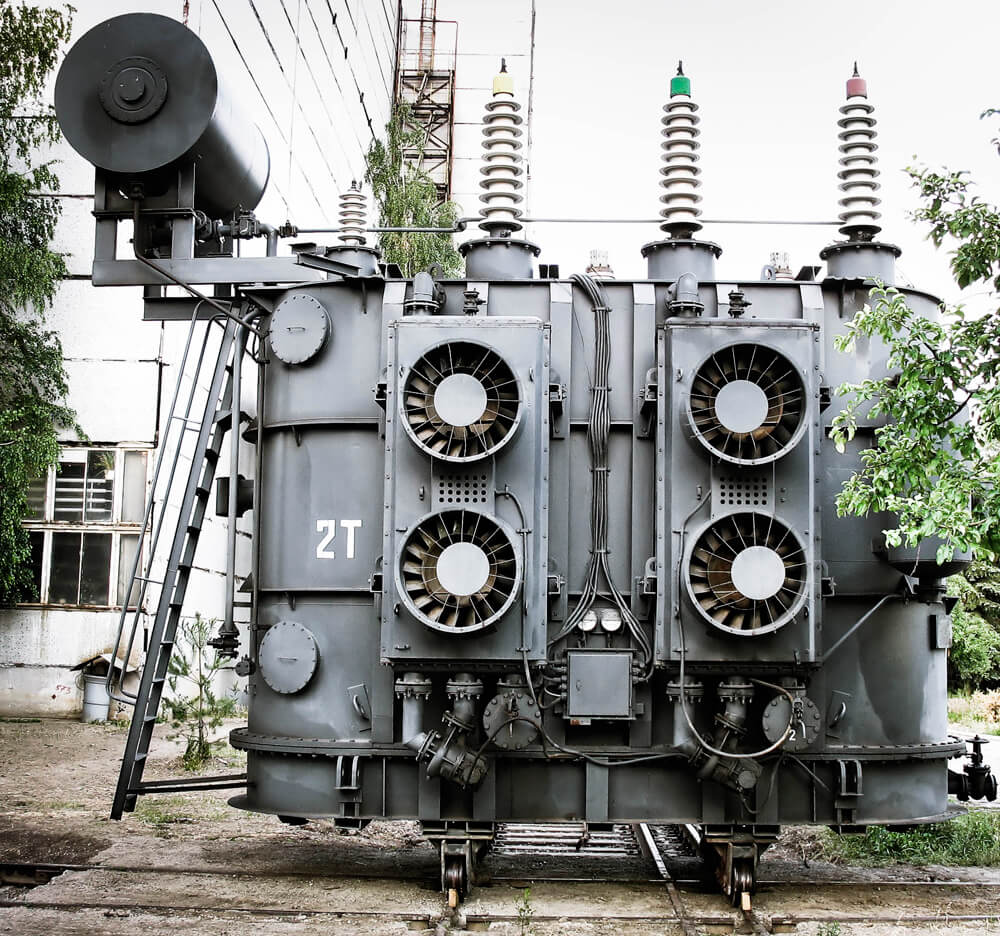

Transformer oil is a customized cooling down and shielding liquid used in electric transformers to improve functional efficiency and reliability. This oil plays a vital function in stopping electrical discharges and maintaining the essential thermal equilibrium within the transformer - Recycling Transformer Oil. It offers to shield the conductive elements, guaranteeing that energy is properly moved while reducing the risk of brief circuits

Normally originated from refined oil, transformer oil is defined by its high dielectric strength, reduced viscosity, and a durable chemical stability that allows it to hold up against raised temperatures. The oil's capacity to dissipate warm generated throughout operation is pivotal; as transformers transform electric energy, they create heat that has to be properly handled to avoid devices failure.

In addition, transformer oil is developed to withstand oxidation and destruction, which can cause the formation of sludge and various other hazardous results. Regular surveillance of oil high quality is essential, as pollutants can compromise its protecting homes and total performance. Understanding the composition and performance of transformer oil is essential for upkeep practices, guaranteeing the durability and functional stability of transformers in various applications across the power industry.

Importance of Recycling

Why is reusing transformer oil vital for both environmental sustainability and economic performance? The improper disposal of transformer oil can bring about severe environmental hazards, consisting of soil and water contamination. By recycling this beneficial resource, we not just alleviate these threats yet also add to a cleaner ecosystem. Utilized transformer oil has hazardous materials that, if launched into the environment, can hurt wildlife and disrupt local ecosystems. Reusing helps to stop these unfavorable effects, reinforcing the dedication to ecological stewardship.

From a financial point of view, reusing transformer oil presents substantial expense savings for companies. The process enables companies to redeem a high-quality product that can be reused in numerous applications, reducing the requirement for purchasing brand-new oil. This not just lowers operational prices yet additionally minimizes garbage disposal expenses connected with unsafe products. Additionally, recycling sustains the circular economy by transforming waste into beneficial sources, thereby promoting lasting techniques within the sector.

Advanced Recycling Technologies

As the need for sustainable techniques in the power sector grows, progressed reusing innovations have emerged as an essential option for processing made use of transformer oil. These modern technologies include a series of cutting-edge methods developed to successfully redeem important resources while reducing environmental influence.

One famous method is vacuum cleaner distillation, which divides oil components at reduced temperatures, maintaining the quality of the base oil while getting rid of impurities. This approach enhances the recuperation rate and ensures that the recycled oil satisfies industry criteria. Another significant development is using adsorption and filtration systems, which utilize specialized products to catch pollutants and recover the oil's properties effectively.

Moreover, the combination of chemical treatments, such as neutralization and decolorization, plays a vital function in refining transformer oil. These processes remove acids, sludge, and discoloration, causing high-grade recycled oil that can be recycled in various applications.

Economic and Environmental Benefits

The financial and ecological benefits of transformer oil recycling are considerable, offering a dual advantage for both market stakeholders and ecological conservation. By reprocessing utilized transformer oil, business can significantly reduce operational prices connected with purchasing new oil, hence improving their profits. This process not just reduces garbage disposal fees yet also permits for the recovery of useful materials, why not find out more producing added income streams.

From an ecological point of view, reusing transformer oil contributes to a reduction in air pollution and resource exhaustion (Transformer Oil Purification). Correct recycling procedures reduce the danger of hazardous spills and soil contamination, advertising and securing neighborhood ecosystems biodiversity. Repurposing transformer oil decreases the need for virgin oil extraction, which usually involves environmentally devastating techniques such as boring and refining.

Furthermore, taking on innovative reusing innovations enhances conformity with stringent ecological guidelines, thus securing companies from prospective liabilities and fines. The favorable influence on company social responsibility campaigns can improve a company's reputation, cultivating greater count on and commitment amongst customers and stakeholders. Fundamentally, the environmental and economic advantages of transformer oil recycling underscore its significance as a sustainable technique in the energy sector.

Future of Transformer Oil Recycling

Structure on the considerable economic and ecological benefits highlighted, the future of transformer oil recycling appears appealing, driven by technological improvements and raising regulatory stress. Innovations in reusing modern technologies, such as enhanced filtration systems and chemical handling techniques, are expected to enhance the performance and effectiveness of oil recuperation processes. These developments not only minimize waste however additionally optimize the high quality of recycled oil, making it better for reuse in different applications.

Moreover, as federal governments and governing bodies worldwide apply more stringent environmental guidelines, the demand for sustainable practices will certainly climb. This shift will Website oblige markets to embrace transformer oil recycling as an essential element of their operational approaches. Companies that prioritize eco-friendly methods are likely to gain an one-upmanship, interesting environmentally aware consumers and stakeholders.

Verdict

The recycling of transformer oil with sophisticated modern technologies not only saves valuable sources but likewise dramatically alleviates environmental dangers connected with garbage disposal. By taking on ingenious techniques such as vacuum cleaner distillation and purification, the electrical market can boost sustainability while all at once minimizing operational prices and generating revenue. As the focus on green methods increases, the future of transformer oil recycling shows up promising, positioning firms to flourish in a significantly affordable address market that prioritizes sustainability and ecological duty.

Transformer oil is a specific cooling and insulating liquid made use of in electrical transformers to enhance operational performance and integrity. Comprehending the structure and functionality of transformer oil is crucial for upkeep practices, making sure the longevity and operational stability of transformers in various applications across the power sector.

One popular technique is vacuum distillation, which divides oil parts at lower temperature levels, preserving the quality of the base oil while eliminating contaminants. By reprocessing used transformer oil, companies can dramatically minimize functional costs associated with buying new oil, therefore enhancing their lower line. Repurposing transformer oil reduces the need for virgin oil removal, which typically includes ecologically harmful techniques such as drilling and refining.

Report this page